gbracing

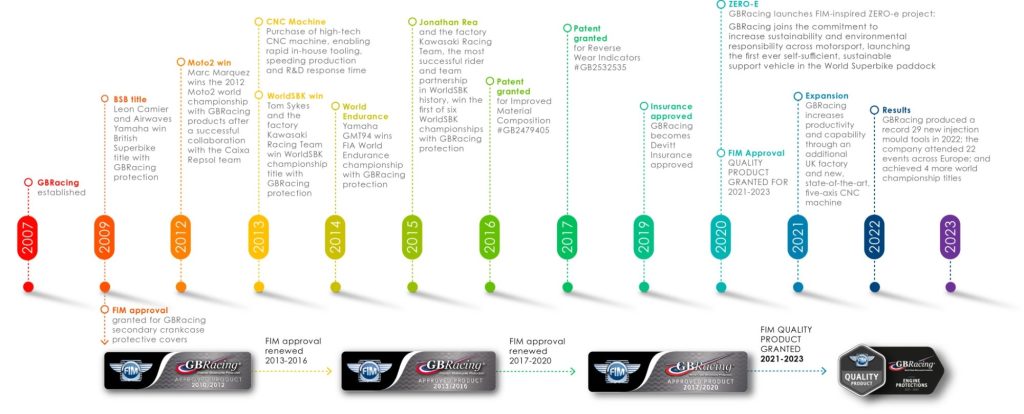

Founded in 2007, GBRacing

has established itself as the market leader in motorcycle protection products, supporting race teams and road riders worldwide.

about GBRacing

With nearly 100 years of engineering experience and expertise, stemming from our parent company Lewis Banks Ltd, our design and development of secondary engine covers is unparalleled in the industry. We utilise leading CAD software to create original design concepts and manufacture using the most advanced engineering materials and injection-moulding plant available.

In 2009 we gained the prestigious Federation of International Motorcyclists (FIM) accreditation and we are the only FIM-approved product range worldwide. Our company culture has been key to this success; our employees work together as a team to provide the very highest standards of product quality and excellent levels of customer service. The company has grown significantly in its short life and we have worked very closely at the highest level of world championship motorcycle racing to develop, continually improve and enhance our product portfolio.

Our continued and growing commitment to the BSB, WorldSBK and MotoGP paddocks enable us to grow our product range with the insight and cooperation of some of the world’s best teams and racing engineers. 3D software enables us to digitally share models with our customers and race teams quickly and efficiently while 3D printing allows us to rigorously test each part prior to production. Whilst our primary focus has been in the sports motorcycle market, moving forward our mission is to expand our product range into adjacent motorcycle sectors, growing our company philosophy and passion for motorcycle protection.

In 2009 we gained the prestigious Federation of International Motorcyclists (FIM) accreditation and we are the only FIM-approved product range worldwide. Our company culture has been key to this success; our employees work together as a team to provide the very highest standards of product quality and excellent levels of customer service. The company has grown significantly in its short life and we have worked very closely at the highest level of world championship motorcycle racing to develop, continually improve and enhance our product portfolio.

Our continued and growing commitment to the BSB, WorldSBK and MotoGP paddocks enable us to grow our product range with the insight and cooperation of some of the world’s best teams and racing engineers. 3D software enables us to digitally share models with our customers and race teams quickly and efficiently while 3D printing allows us to rigorously test each part prior to production. Whilst our primary focus has been in the sports motorcycle market, moving forward our mission is to expand our product range into adjacent motorcycle sectors, growing our company philosophy and passion for motorcycle protection.

why gbracing

GBRacing products are the benchmark in high-performance, bolt-on motorcycle protection for the short circuit, road racing and street bike community. We are the only manufacturer of motorcycle protection to have received FIM product approval, a mark of quality we’ve carried since 2009. This has now been renewed for 2021 through to 2023 on our range of bolt-on secondary engine covers.

Championships cover IDM, AMA, CIV, IDM, FFM EWC, BSB, WorldSBK, MotoGP and more. We also have two patents granted: Improved Composition (Patent #GB2479405) for the material used in our engine protection and a patent for our Reverse Wear Indicators Indicators (Patent #GB2532535).

design

Each product is specifically designed, engineered and manufactured to deliver the best overall quality protection. Our core product range is our FIM-approved bolt-on secondary engine covers. We vary the thickness of the injection-moulded material from 2mm to 12mm to give maximum engine protection without compromising ground clearance or weight.

Our crash bobbins, frame sliders and Bullet Sliders are engineered with the same exacting level of care and attention to detail. They dissipate force in their structure and are designed to bend under heavy forces rather than transfer these potential forces to the bike. They greatly reduce the possibility of ‘flipping the bike’ and potentially causing more damage.

Our crash bobbins, frame sliders and Bullet Sliders are engineered with the same exacting level of care and attention to detail. They dissipate force in their structure and are designed to bend under heavy forces rather than transfer these potential forces to the bike. They greatly reduce the possibility of ‘flipping the bike’ and potentially causing more damage.

Read more

Our Bullet Sliders are manufactured in two versions. The ‘Race’ version, which sits beneath or parallel with the fairing, and concentrates on protecting the frame, radiator and other areas that can prove difficult to repair in between sessions or races. We also have the ‘Street’ version. This version protrudes beyond the fairing, where damage to the original road fairing can be costly and is therefore a high priority. Both provide another point of contact in the event of a crash.

TEAM DEVELOPMENT

We are continually developing and improving our crash protection products utilising invaluable team and customer feedback.

By attending all British Superbike and European World Superbike events throughout the year, we are able to gain real-time feedback on our products and discuss new ways in which to develop and enhance track safety. This is also a stage to explore new designs and ideas around the industry with the very best teams and race engineers worldwide.

By attending all British Superbike and European World Superbike events throughout the year, we are able to gain real-time feedback on our products and discuss new ways in which to develop and enhance track safety. This is also a stage to explore new designs and ideas around the industry with the very best teams and race engineers worldwide.