ABOUT

LEWIS BANKS LTD

Who we are and what we do

Lewis Banks Ltd draws on over 100 years of experience dating back to 1916.

We adapt to projects across a variety industries: consistently delivering on time, budget and quality. From concept to worldwide distribution, we do everything in house allowing us to stay lean and flexible to customer requirements.

As a family run business, all projects have a personal touch; honesty and passion are at the forefront of everything we do. With our wider team of 26 and growing, we take great pride in every product that leaves our door, and we are all committed to going above and beyond, with clear communication throughout.

Life cycle of an idea

PART DESIGN AND TESTING

We don't just design parts; we solve problems.

Utilising experience and expertise we can advise across many industries and applications.

3D scanning enables us to build accurate digital models: 3D printing allows us to rigorously test.

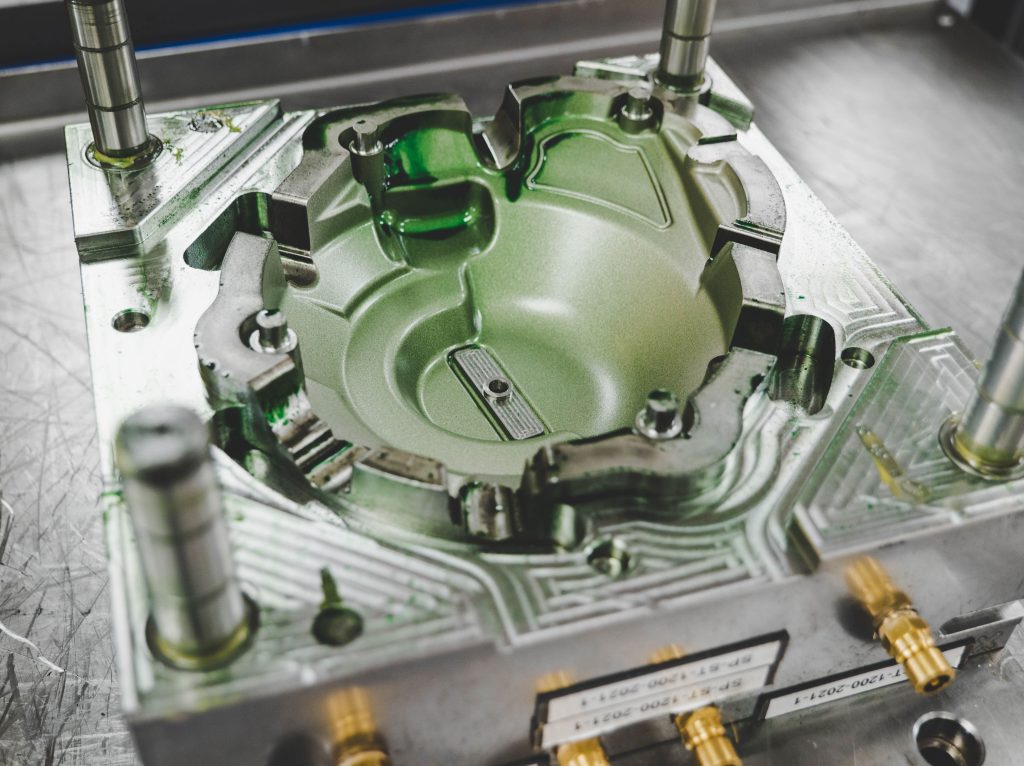

tool design

Tool design balances product requirements with mouldability, quantities and budgets.

tool manufacture

All tooling is run on our XYZ UMC-SX with Heidenheim controller.

Using our universal Georg Fischer Form 20 EDM we achieve the required finish.

production

Moulding typically occurs on one of our Arburg moulding machines ranging from 20-150 tonne.

After moulding, all products are individually quality checked, assembled as required, packaged and ready to ship.

Warehousing and part call offs are available.

MATERIALS WE WORK WITH...

Motosport

Marine

– White or colour matched

– High strength, with flexibility

– Used on GBMarine mast brackets

people at heart of what we do